Quantitative assessment of regional biomass-based value chains

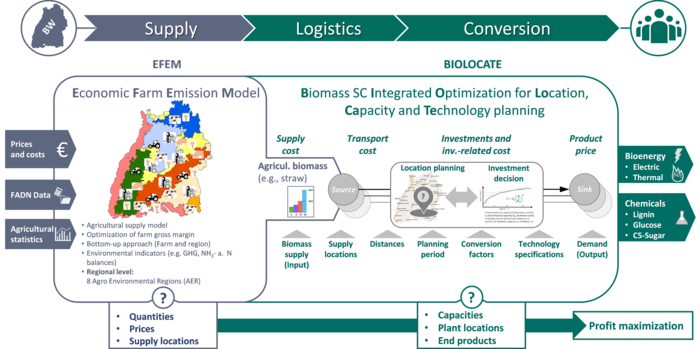

The aim of the subproject was to promote the development and dissemination of technologies for the energetic and material use of biomass and products in Baden-Württemberg. An integrated model that was developed as part of the tri-national project "Innovations for a sustainable use of biomass in the Upper Rhine region", which was adapted and extended for Baden-Württemberg with high spatial resolution, is applied. The model is based on material and energy flows for existing processes (e.g. biomass combustion) and for new biomass utilization concepts (e.g. biorefineries) as well as their techno-economic and ecological parameters. In cooperation with subprojects of the biogas and lignocellulose research network, a working group "BEPAF-BW" was set up to investigate the use of agricultural and forestry potential for bioeconomy in Baden-Württemberg (BioEconomy Potential from Agriculture and Forestry). An example of an implemented model linkage is the iterative coupling of the agricultural supply model EFEM (Economic Farm Emission Model) with the techno-economic location optimization model BiOLoCaTe (Biomass value chain Integrated Optimization for Location, Capacity, and Technology planning). The model linkage made it possible to identify potential locations of conversion plants for agricultural biomass in Baden-Württemberg (Figure 1).

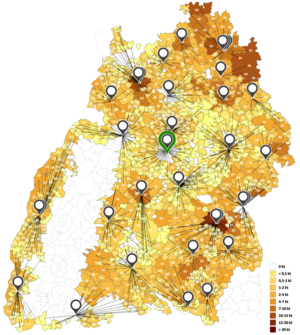

The application of the model linkage is described below for the example of site optimization of combustion plants and biorefineries for the energetic and material utilization of straw. This is based on the linking of price-dependent quantities of straw in Baden-Württemberg and thus enables a detailed mapping of biomass-based value chains. This enables to evaluate different conversion technologies. Figure 2 summarizes the results of the energy and material utilization of straw and shows the distribution of straw combustion plants and a biorefinery.

The Institute for Industrial Production (IIP) at KIT consists of an international team conducting interdisciplinary and application-oriented research. Numerous projects in the field of techno-economic analysis of strategies for sustainable use of biomass, process and product evaluation, and the development of production, logistics, and disposal concepts have been successfully carried out.

| Project title | Quantitative assessment of regional biomass-based value chains |

| Institution | Karlsruhe Institute of Technology (KIT), Institute for Industrial Production (IIP) |

| Research group | Prof. Dr. Frank Schultmann, M.Sc. Andreas Rudi |

| Project status | completed |